Metal stamping is a cold-forming manufacturing process that uses specialized tools (i.e., dies) and equipment (i.e., presses) to form and cut sheet metal into various shapes and sizes. At the start of a stamping operation, the die(s) is/are installed within the press(es), which provide(s) the force needed to turn the material into the desired component. While stamping dies may vary from project to project depending on the part and production needs, they can be categorized into two main groups: single-station dies and multi-station dies. Below, we go into greater detail on the unique characteristics of each type of metal stamping die.

Metal stamping is a cold-forming manufacturing process that uses specialized tools (i.e., dies) and equipment (i.e., presses) to form and cut sheet metal into various shapes and sizes. At the start of a stamping operation, the die(s) is/are installed within the press(es), which provide(s) the force needed to turn the material into the desired component. While stamping dies may vary from project to project depending on the part and production needs, they can be categorized into two main groups: single-station dies and multi-station dies. Below, we go into greater detail on the unique characteristics of each type of metal stamping die.

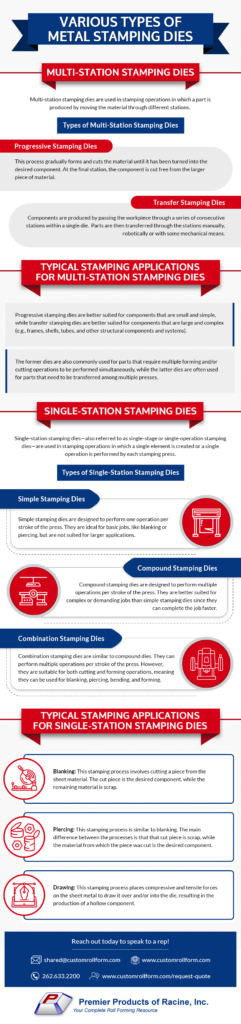

Multi-Station Stamping Dies

Multi-station stamping dies are used in stamping operations in which a part is produced by moving the material through different stations. These dies come in series; each die in the series makes slight changes to the workpiece that gradually forms and cuts it into the desired shape and size.

Types of Multi-Station Stamping Dies

The two main types of multi-station stamping dies are progressive stamping dies and transfer stamping dies.

Progressive Stamping Dies

In progressive stamping operations, each station in the die performs a specific task within the press. Once the task is completed, the workpiece is automatically moved to the next station. This process gradually forms and cuts the material until it has been turned into the desired component. At the final station, the component is cut free from the larger piece of material.

Transfer Stamping Dies

The transfer die stamping process is highly similar to the progressive die stamping process; components are produced by passing the workpiece through a series of consecutive stations within a single die. The main difference between the two processes is that the component is cut from the sheet metal at the beginning rather than the end. Parts are then transferred through the stations manually, robotically or with some mechanical means.

Typical Stamping Applications for Multi-Station Stamping Dies

Both progressive stamping dies and transfer stamping dies are widely used for stamping projects. However, given the difference in their processes, they are utilized for different types of projects. Progressive stamping dies are better suited for components that are small and simple, while transfer stamping dies are better suited for components that are large and complex (e.g., frames, shells, tubes, and other structural components and systems). The former dies are also commonly used for parts that require multiple forming and/or cutting operations to be performed simultaneously, while the latter dies are often used for parts that need to be transferred among multiple presses.

Single-Station Stamping Dies

Single-station stamping dies—also referred to as single-stage or single-operation stamping dies—are used in stamping operations in which a single element is created or a single operation is performed by each stamping press. If multiple elements and/or operations are needed to produce a finished component, the workpiece must be moved from press to press until it is completed, which can be time-consuming. That’s why these dies are generally used for simple parts and products and low-volume production runs.

Types of Single-Station Stamping Dies

Some of the most commonly used single-station stamping dies are simple stamping dies, compound stamping dies, and combination stamping dies.

Simple Stamping Dies

Simple stamping dies are designed to perform one operation per stroke of the press. They are ideal for basic jobs, like blanking or piercing, but are not suited for larger applications.

Compound Stamping Dies

Compound stamping dies are designed to perform multiple operations per stroke of the press. They are better suited for complex or demanding jobs than simple stamping dies since they can complete the job faster. However, while they can handle cutting operations (e.g., blanking and piercing), they are not ideal for forming operations (e.g., bending).

Combination Stamping Dies

Combination stamping dies are similar to compound dies. They can perform multiple operations per stroke of the press. However, they are suitable for both cutting and forming operations, meaning they can be used for blanking, piercing, bending, and forming.

Typical Stamping Applications for Single-Station Stamping Dies

Single-station dies can be used for a variety of stamping operations, including:

- Blanking: This stamping process involves cutting a piece from the sheet material. The cut piece is the desired component, while the remaining material is scrap.

- Piercing: This stamping process is similar to blanking. The main difference between the processes is that that cut piece is scrap, while the material from which the piece was cut is the desired component.

- Drawing: This stamping process places compressive and tensile forces on the sheet metal to draw it over and/or into the die, resulting in the production of a hollow component.

Learn More About Metal Stamping Dies From Premier Products of Racine

Want additional information on the different types of metal stamping dies? Ask the experts at Premier Products of Racine. Equipped with extensive custom metal stamping experience, we can answer any questions and address any concerns you may have about these components. Additionally, if you need a partner for your next metal stamping project, we’ve got you covered. Contact us or request a quote today to discuss your project with one of our representatives.

Comments are closed