Premier Products of Racine is a full-service metal manufacturing company. We offer a range of fabrication and finishing capabilities to customers across a variety of industries, ensuring we can develop and deliver the quality parts and products they need at competitive prices.

Premier Products of Racine is a full-service metal manufacturing company. We offer a range of fabrication and finishing capabilities to customers across a variety of industries, ensuring we can develop and deliver the quality parts and products they need at competitive prices.

One of our core service offerings is assembly. Throughout our over two decades in business, we’ve come to understand that creating a component is only one aspect of manufacturing a finished part or product. Manufacturing projects often require the combination of multiple components into a single unit. We provide this service to our customers, turning their assembly problems into solutions.

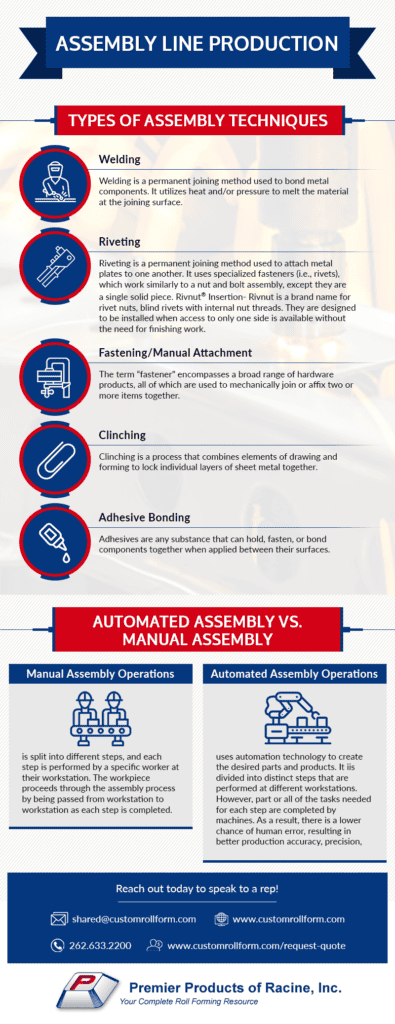

Types of Assembly Techniques

There are many types of assembly techniques available, each of which is suitable for different assembly needs. We offer the following capabilities:

Welding

Welding is a permanent joining method used to bond metal components. It utilizes heat and/or pressure to melt the material at the joining surface. The joint is formed when the material resolidifies. Commonly used welding processes include MIG and TIG welding.

Riveting

Riveting is a permanent joining method used to attach metal plates to one another. It uses specialized fasteners (i.e., rivets), which work similarly to a nut and bolt assembly, except they are a single solid piece. The two main types of rivets uses are solid rivets and blind rivets. The former requires access to both sides for installation, while the latter only needs access to one side for installation.

Rivnut® Insertion

Rivnut is a brand name for rivet nuts, blind rivets with internal nut threads. They are designed to be installed when access to only one side is available without the need for finishing work.

Fastening/Manual Attachment

The term “fastener” encompasses a broad range of hardware products, all of which are used to mechanically join or affix two or more items together. In addition to rivets, these products include screws, bolts, nails, and clips. The joints formed between components can be created manually by human workers or automatically by automated fastening systems. Additionally, they are generally non-permanent, meaning they can be disassembled without damaging the individual assembly pieces.

Clinching

Clinching is a process that combines elements of drawing and forming to lock individual layers of sheet metal together. While it is commonly used to join two layers, it can be used for more. It is often utilized as an alternative for welding and fastening methods.

Adhesive Bonding

Adhesives are any substance that can hold, fasten, or bond components together when applied between their surfaces. They are available in various formulations, ranging in strength, reactivity vs. inertness, form, and more. This broad selection enables manufacturers to choose a product that suits their exact assembly needs.

Our team has the expertise and equipment to handle low-volume to high-volume assembly projects. Whether we use manual assembly methods or automated assembly systems, we optimize operations to ensure the best cost-efficiency for customers.

- Manual assembly operations rely on work performed by human workers. The assembly process is split into different steps, and each step is performed by a specific worker at their workstation. The workpiece proceeds through the assembly process by being passed from workstation to workstation as each step is completed. The advantage of this setup is labor specialization—giving each worker a limited amount of tasks that must be performed repeatedly enables them to become an expert in those tasks. As a result, they can complete them with greater consistency and speed.

- Automated assembly operations use automation technology to create the desired parts and products. Similar to the manual assembly process, the automated assembly process is divided into distinct steps that are performed at different workstations. However, part or all of the tasks needed for each step are completed by machines. As a result, there is a lower chance of human error, resulting in better production accuracy, precision, and speed.

Contact Us for Your Assembly Needs Today

Are you facing assembly problems in your next manufacturing project? Let us provide you with a solution. For more information on our assembly capabilities and how they can benefit your next project, contact us today. To discuss your assembly requirements with one of our team members, request a quote.