A customer in appliance manufacturing desired to cut production costs on a current product line. Premier Products of Racine took on the challenge of designing a new part that would exceed expectations and lower costs for the client.

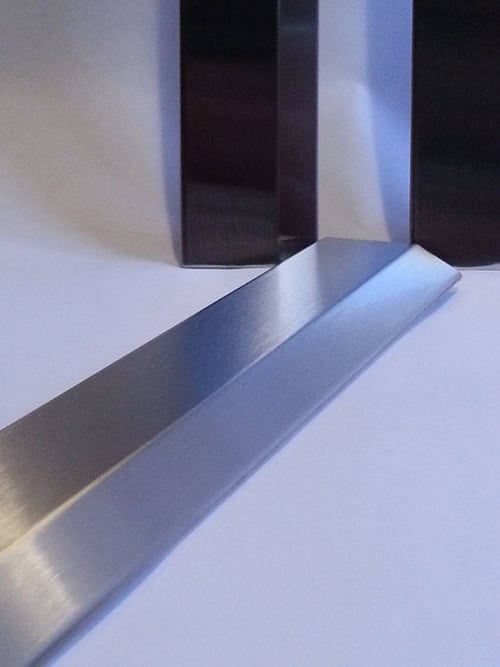

The redesigned grille vane was an excellent match for our specially developed roll forming process due to its simple cross section and high volume. 201 stainless steel was pre-notched and roll formed on our custom-built machinery equipped with in-house designed dies, then cut to the required length.

Our process ensures that the cosmetic material is not damaged during manufacturing. Secondary processes employed include forming and packaging for shipment. All processes took place at our state-of-the-art facility.

Tight tolerance of ±0.005″ was held throughout construction, and a maximum allowance of two 0.020″ or smaller cosmetic defects was maintained along the part’s length. The finished dimensions were 30″ – 73″ long x 0.030″ thick, featuring a highly cosmetic #4 brush finish.

Premier Products is dedicated to being leading innovators in metal roll forming. We cater to customer requirements, offering high quality, cost-effective solutions. For more about this cosmetic stainless steel roll forming project, please see the table below or contact us directly.