At Premier Products of Racine, we are a full-service metal manufacturing company. We provide an extensive selection of fabrication and finishing services to ensure we can deliver complete solutions to our customers.

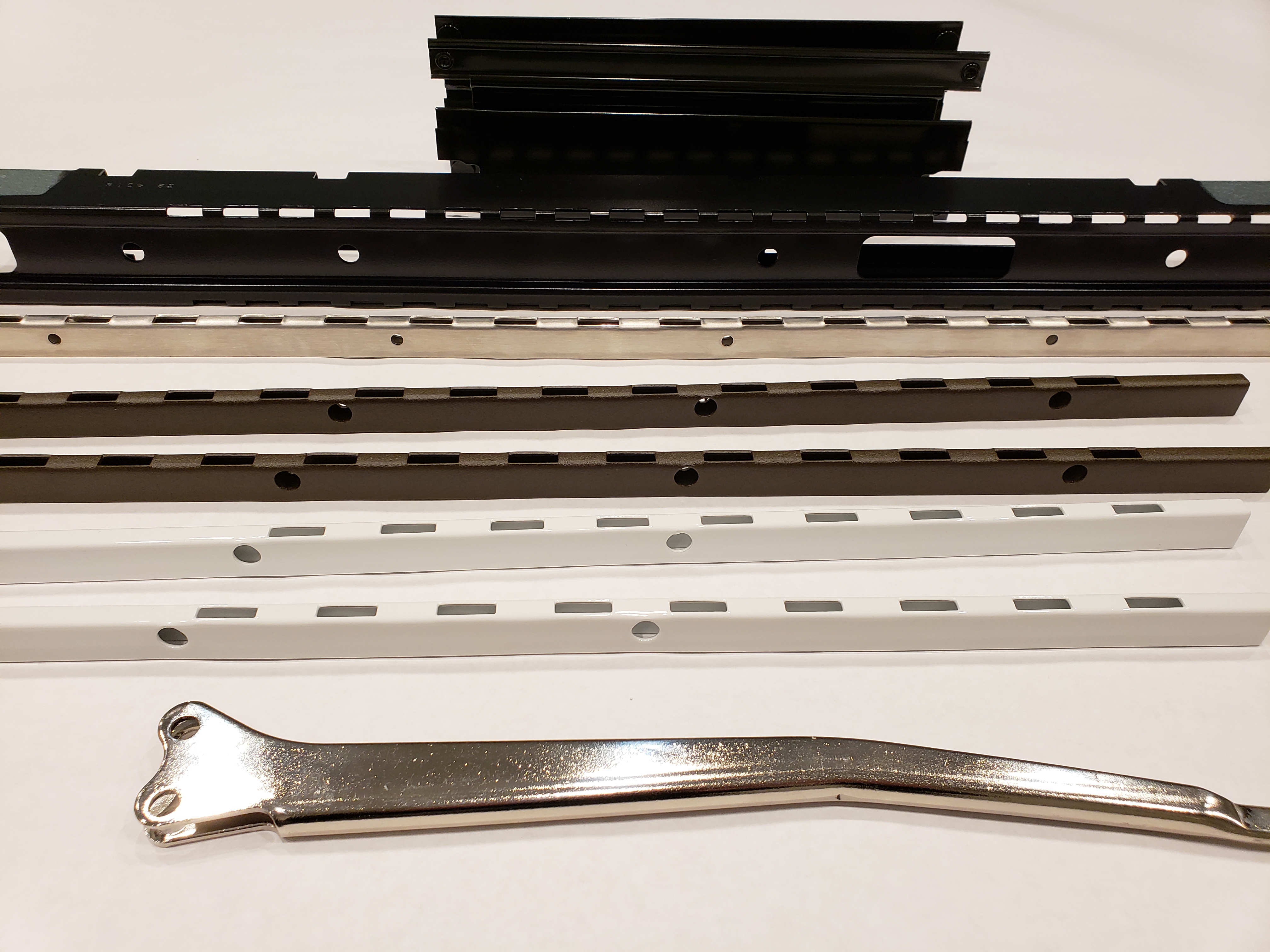

Our team is familiar with all types of secondary finishing techniques, including plating, electroless plating, powder coating, passivation, and hot blackening. Armed with over two decades of experience and a range of finishing equipment, we have the knowledge, skills, and tools to identify and perform the finishing treatments needed to achieve virtually any surface finish on a metal component. Whether a customer needs a specific functional or aesthetic characteristic, we’ve got them covered. If we cannot offer a service directly, we outsource the operation to one of our carefully vetted and highly qualified vendors.

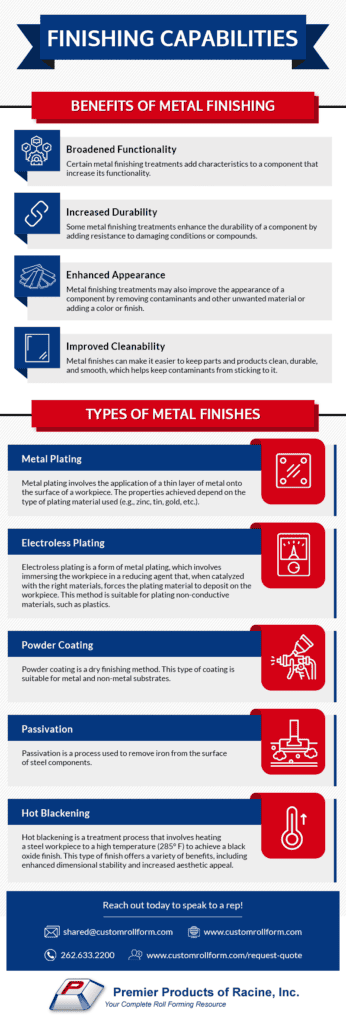

Benefits of Metal Finishing

Benefits of Metal Finishing

Metal finishing treatments alter the surface characteristics of a metal part or product to make it better suited for its application functionally and/or aesthetically. Depending on the type of treatment performed, the surface may have its existing properties enhanced and/or new properties added. Typical benefits of metal finishing include:

- Broadened functionality. Certain metal finishing treatments add characteristics to a component that increase its functionality. For example, they may improve or reduce its electrical conductivity depending on whether it is required for the intended application.

- Increased durability. Some metal finishing treatments enhance the durability of a component by adding resistance to damaging conditions or compounds. For example, they may make the component more resistant to chemicals, corrosion or abrasion.

- Enhanced appearance. Metal finishing treatments may also improve the appearance of a component by removing contaminants and other unwanted material or adding a color or finish. These improvements may result in a more appealing look and feel.

- Improved cleanability. Metal finishes can make it easier to keep parts and products clean. In addition to making the surface of the components more durable, some (e.g., polishing) make it more smooth, which helps keep contaminants from sticking to it.

Types of Metal Finishes

There are many types of metal finishing treatments available. Some of the ones we offer include:

Metal Plating

Metal plating involves the application of a thin layer of metal onto the surface of a workpiece. It is typically performed using the electroplating method, which involves running an electrical current through a metal workpiece submerged in a specialized chemical bath. Some of the main reasons to plate a component include improved appearance, increased corrosion resistance, and enhanced surface hardness. The properties achieved depend on the type of plating material used (e.g., zinc, tin, gold, etc.).

Electroless Plating

Electroless plating is a form of metal plating. Unlike electroplating, it does not use electricity to deposit the plating material on the workpiece. Instead, the workpiece is immersed in a reducing agent that, when catalyzed with the right materials, forces the plating material to deposit on the workpiece. This method is suitable for plating non-conductive materials, such as plastics.

Powder Coating

Powder coating is a dry finishing method. First, a powderized polymer resin mixed with curatives, pigments, leveling agents, flow modifiers, and other additives is applied to the surface. Then, the workpiece is heated to cure the powder. The result is a smooth and durable coating layer. This type of coating is suitable for metal and non-metal substrates.

Passivation

Passivation is a process used to remove iron from the surface of steel components. It produces a more uniform passive surface, which helps improve the piece’s corrosion resistance. It also removes existing surface contaminants and reduces the risk of future contamination.

Hot Blackening

Hot blackening is a treatment process that involves heating a steel workpiece to a high temperature (285° F) to achieve a black oxide finish. This type of finish offers a variety of benefits, including enhanced dimensional stability and increased aesthetic appeal.

Contact Us for Your Metal Finishing Needs Today

Looking for a manufacturing partner that offers full-service solutions? We are here to help! We can handle all fabrication and finishing operations, so you receive a complete metal part or product. For more information on our finishing capabilities, contact us today. To discuss your finishing requirements with one of our team members, request a quote.

Case Studies

- Cosmetic Roll Forming of Stainless Steel Parts for the Appliance Industry

- Stainless Steel Fabrication of a Cosmetic Door Trim for the Consumer Appliance Industry

- Fabrication of Tube Burner for the Barbeque Industry

- Roll Formed Stainless Steel Tanker Truck Structural Beam

- Roll Formed Shelf Ladder for Appliance Industry