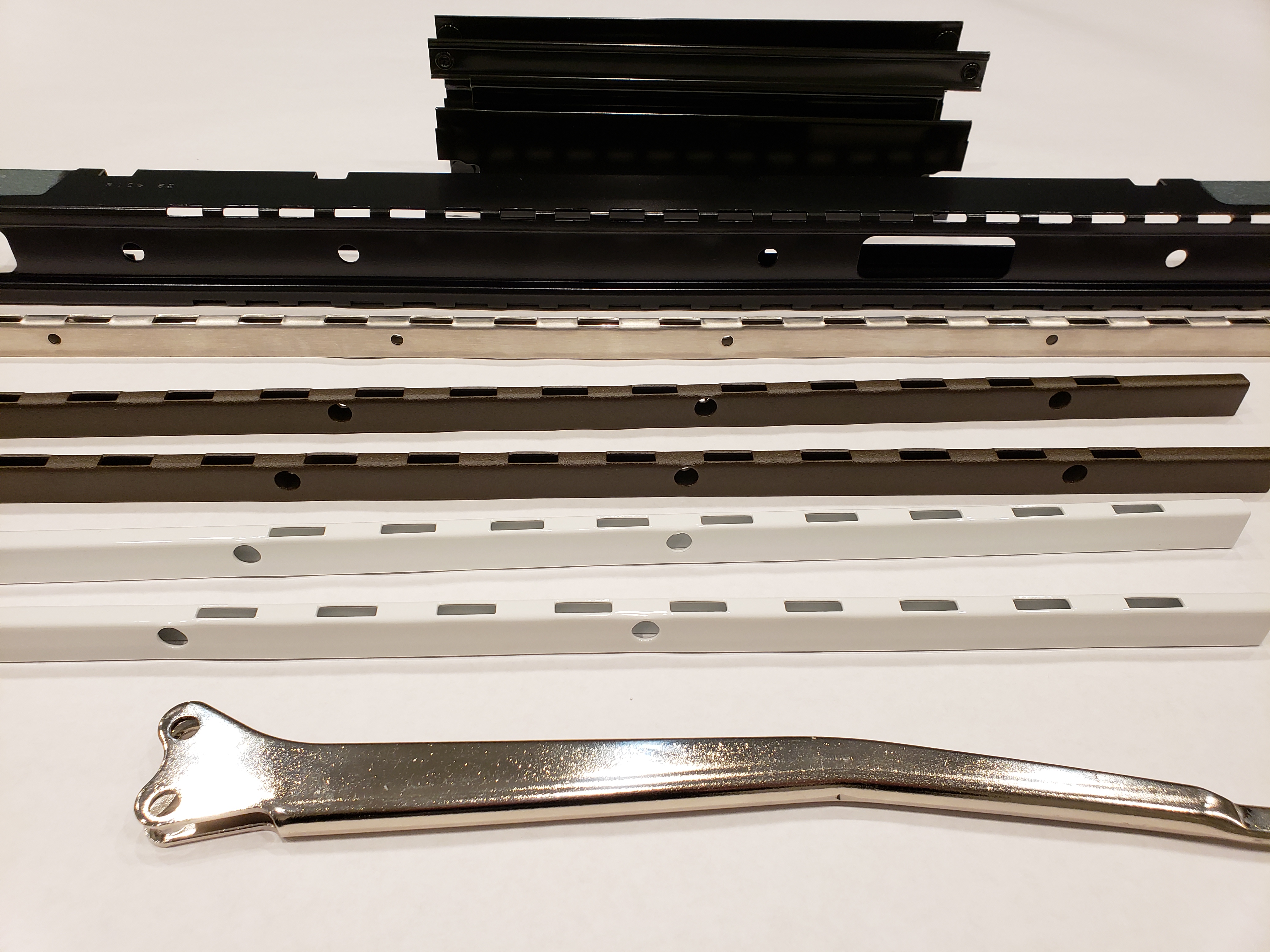

An appliance manufacturer contacted us about a project for a roll formed shelf ladder.

Their current supplier was having difficulties with volumes and Premier Products was up for the challenge. The most difficult aspect of this product group being there were 28 different unique lengths, hole patterns and different base materials that require a huge amount of time for changeover. We were able to design a tooling approach coupled with our in-house automation systems that allowed changeover to happen within 30 seconds at the touch of a button.

A fully automated pre-notch tool reconfigures itself with a combination of movable die sections and gaggable punches to produce all of these unique parts without any room for error. The tooling allowed us to create sections from 12” – 56” long in either cold rolled steel, or cosmetic #4 brushed stainless steel at speeds up to 60 feet/minute.

Premier Products is dedicated to providing innovative solutions to difficult problems. Our engineering and tooling expertise will be abundantly clear through the entire design process. For more information about our custom roll forming solutions using state of the art automation systems please contact us directly or request a quote.